Home | Areas of expertise | Products | Assemblies

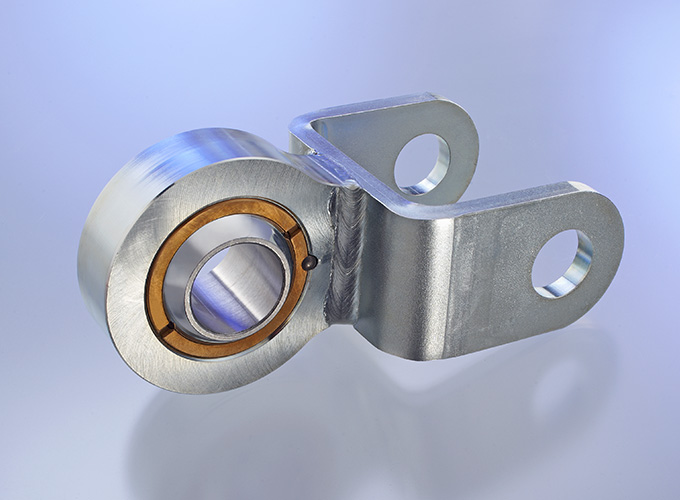

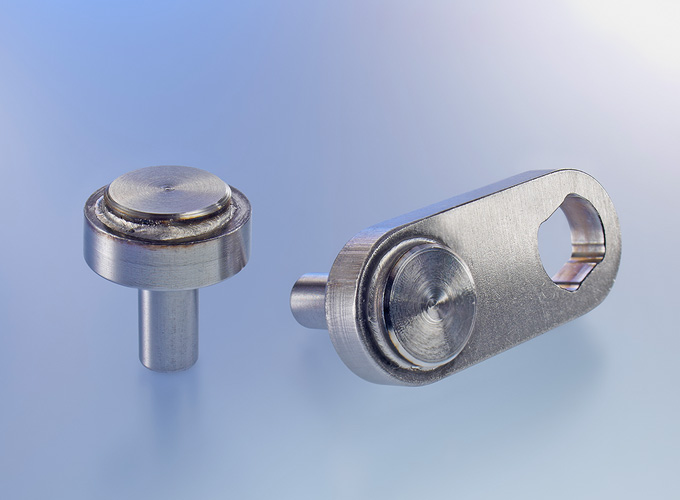

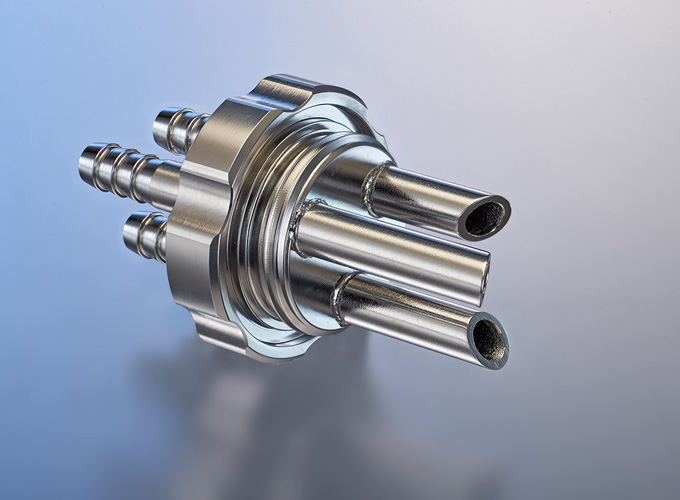

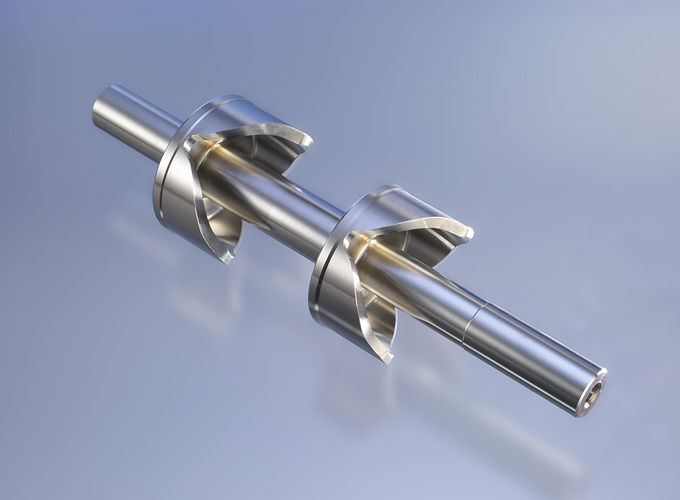

Precision parts from HÖHN are used across the globe in the most demanding applications and industries: turned parts, milled parts, ground parts and more – customised and in top quality.

Our range of services includes a wide variety of different materials (steels, stainless steels, non-ferrous metals, special alloys, plastics and special materials etc.) and processing methods which we combine together depending on the requirement. This is how we not only offer the best possible solutions for the specific needs of our customers, but implement them with optimal efficiency as well.

A team of 160 trained specialists, in conjunction with a high-performance machine and system park, enable even highly complex requirements to become a reality. The result of this versatility is a maximum of options for our customers. We at HÖHN not only see ourselves as a reliable manufacturer of precision parts, but, more importantly, as a company who understand our customers and solve problems.

Looking for a capable and reliable manufacturer of precision parts? You’re in the right place.

Efficiency, quality and reliability – these are the cornerstones of our component assembly. We are your reliable partner in the fields of robotics, automation, aviation, food processing, packaging and dosing systems as well as environmental technology.

State-of-the-art production – precision at its highest level

Our machine part includes powerful CNC lathes and mills as well as high-precision grinding machines. In addition to these, we also have special assembly lines for mechanical modules. Thanks to this equipment, we are able to guarantee fault-free production and assembly – even where the requirements are demanding.

Your advantages at a glance:

As an experienced system supplier, we take care of the entire process for you: from procurement of the individual parts and their production in our own machining shop – through turning and milling of materials such as V4A, quenched and tempered steel, castings, steel, aluminium and non-ferrous metals – right up to finishing with common surface treatments such as galvanising, burnishing, passivation, anodising, hard anodising, hard chromium plating or chemical nickel plating. The subsequent assembly, final inspection and well-organised logistics round of our service portfolio.

By outsourcing your component assembly to HÖHN, you not only save time and human resources but also benefit from our many years of experience, our modern machine park and our optimised supply chain. Thanks to skeleton agreements and our fully automatic warehouse with generous capacities, we deliver just in time. Lean organisation, FIFO-compliant order picking and software-aided production control ensure transparency and rapid response. We also react flexibly to customer requests in the final packaging and shipment.

Whether it be mechanical or pneumatic modules – HÖHN is your competent partner for tailor-made solutions. You get everything from a single source – including manufacture of the parts required for your component. We rely on state-of-the-art technologies and maximum precision in our production.

We are able to successfully implement manual, semi-automatic and automatic assembly processes. You give us your drawing – we take care of the rest. Hereby, we not only take all of the defined quality demands defined by the customer into consideration but also apply our own high standards additionally. Our structured mode of procedure ensures that every project is executed efficiently and with assured quality:

Our strengths in the manufacture of precision parts

We rely on state-of-the-art production methods and extensive competence in the production of parts with the highest precision and quality.

For our extensive product range – including coupling, connecting elements and individual drawing parts – we use many different manufacturing processes:

Parts are machined by laser or water jet cutting, for larger quantities also stamped or produced in aluminium, steel stainless steel or investment casting processes.

For the labelling too we offer variable solutions: from engraving in the machining production through dot peening, etching, laser marking to inkjet marking – depending on the material, area of application and customer specifications.

We are your reliable partner for component assembly in the fields of robotics, automation, aviation, food processing, packing and dosing systems as well as environmental technology.